An exhaustive buying guide on chemical anchors, the optimal fixing solution for the transfer of loads on masonry, concrete or cellular concrete. Characteristics, types and scope.

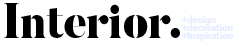

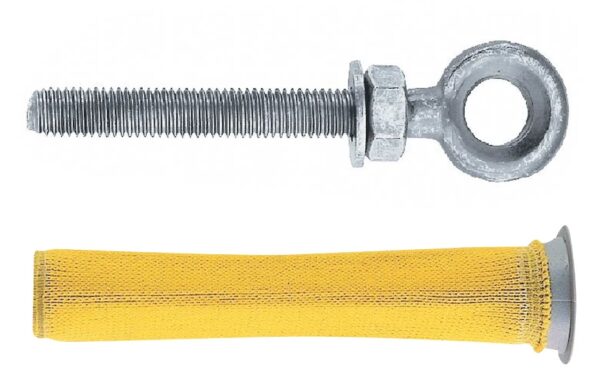

Install satellite dishes, mount awnings, anchor railings. There are many daily activities in which it is essential to fix the masonry. THE chemical anchors they represent an effective solution, whenever the state of the wall does not allow the use of the more traditional mechanical anchor. Its use could in fact shatter the wall, following a greater pressure exerted during the fixing phase.

A technique that allows you to anchor a metal bar in the wall through a glue special inserted into the hole. Once hardened, the screw will be locked. An uncomplicated procedure but which requires competence in the intervention and knowledge in the application of the right products.

Read also: External railings

Let’s find out in our buying guide how chemical anchors work, the types, the capacity and all the other characteristics of this fixing system.

What are chemical anchors?

The chemical anchors represent the solution in transfer loads on masonry, cement and concrete. In addition to the heavier structural workings, there are several common situations in which they can be particularly useful, for example for attach shelves or lamps to the walls of the house, in the assembly of railings, in the construction of canopies.

Whenever the use of mechanical anchors involves the risk of cracks forming on the walls, chemical anchors must be preferred. To this end, recourse is made to special synthetic resins for filling holes, generating the double advantage of improve the tightness of screws and walls.

Generally speaking, chemical anchors are extremely useful in renovations and find frequent application in a multitude of domestic uses.

How are chemical anchors used?

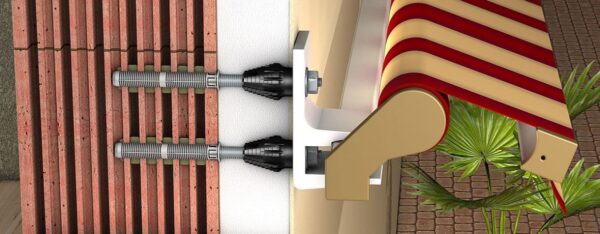

The operation of the chemical anchors is based on the filling of holes with synthetic resins. The purpose is to increase the tightness of the screw inserted inside. These special adhesives harden and guarantee a greater holding of the anchor. In this way the screw and the wall become one, ensuring considerable solidity.

For a correct functioning of the chemical plug it is therefore essential to make use of special resins, the latter characterized by high mechanical strength and speed in hardening.

You may be interested in: Balcony railings

The so-called are commercially available two-component resins, whose application takes place using a gun and a special dispenser. Once opened, the resin is released through a spiral nozzle.

Chemical dowels scope how it works

A fastening technique that stands out for its extreme versatility, even in the presence of one wall with solid or hollow bricks. Usually the steps to take are as follows:

- Drilling

- Cleaning the hole from dust

- Inserting the vial (resin)

- Inserting the bolt or bar

- Rotation and hardening.

Therefore it is essential to inject the resin into the hole before inserting the bar, ensuring a greater airtightness and impermeability to water.

You can insert bars of any length and into the hole increase its range. A larger diameter therefore leads to an increase in load capacity. The chemical anchors therefore allow the flow distribution over the whole area unlike mechanical ones.

Types of resin

At the basis of the functioning of the chemical anchors, the choice of the type of resins and adhesives. A first important classification must be made on the basis of hardening times. A second, taking into account the composition. In this regard, it is necessary to distinguish:

- Polyester

- Epoxy resins

- Vinylester.

The polyester resins they are to be excluded for wet concrete wall works, as they can compromise the solidity and resistance of the entire wall. Therefore, they have a limit in their application due to problems related to alkaline hydrolysis. In this case, the vinylester resins capable of guaranteeing greater mechanical resistance.

In all jobs where more ductility is required, such as holes of a certain width, it is better to prefer epoxy resins, among other things characterized by longer hardening times than the other types described above.

Advantages chemical dowels

From what has been described up to now, the use of chemical anchors has many advantages. One of the main ones is withstand high loads and ensure a remarkable speed of application. Among the strengths of this fixing solution we indicate the resistance to heat and chemical materials, greater durability over time, high anchoring properties. The positives don’t end here though:

- Filling of irregular holes

- Homogeneous pressure distribution

- Dimensions of different fixing diameters

- Edge installation

- Adaptability to multiple materials

Chemical anchor vs mechanical anchor: difference

The chemical anchor ensures one more flexibility compared to a mechanical anchoring. The latter, when inserted into the mural work, is subject to expand during the tightening phase. With brick and stone, for example, using screws that generate expansion in the anchors can affect the integrity of the entire structure and give rise to cracks.

Through the chemical injection into the hole and the use of a threaded rod inside it, the anchoring product is able to withstand considerable load capacities. While It does not “stress” the structure too much but distributes the pressure exerted evenly.

Price chemical dowels

The prices of dowels for chemical anchors are different based on the composition, type and set of accessories included (for example threaded rods). They still present costs within everyone’s reach. Only in some cases they require a few tens of euros more, for specific accessories and high performance anchors for heavy loads. Among the most supplied several specialized chains (Leroy Merlin, Bricoman) and industry brands (for example i Hilti chemical anchors).

Leroy Merlin chemical dowels

Extensive catalog on the online site and in the shops of the well-known brand Leroy Merlin. Dowels, cartridges and chemical anchoring sets are available Fischer line for multiple uses. Prices start at a few euros.

Bricoman chemical dowels

Here is another very popular brand, with a chain of stores scattered throughout the country and a vast online catalog to buy comfortably from PC, smartphone and tablet. Several proposals for chemical anchors of the Fischer, Friulsider, G&B and Wurth lines. Prices for dowels and accessories included from 1 € to a maximum of 86 €.

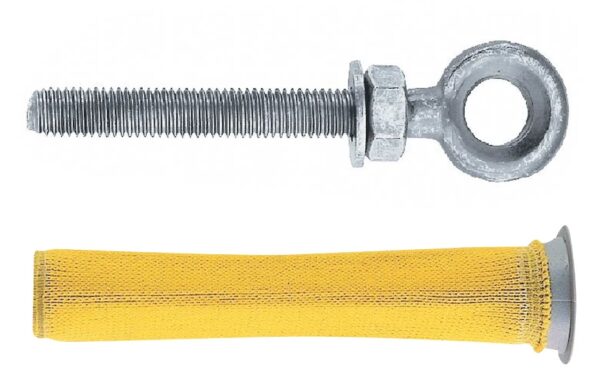

Chemical anchors: photos and images

Below is a complete gallery of images to describe the fixing technique of the chemical anchors and the main characteristics. It can be useful in your future interior and exterior works.

An exhaustive buying guide on chemical anchors, the optimal fixing solution for the transfer of loads on masonry, concrete or cellular concrete. Characteristics, types and scope.

Install satellite dishes, mount awnings, anchor railings. There are many daily activities in which it is essential to fix the masonry. THE chemical anchors they represent an effective solution, whenever the state of the wall does not allow the use of the more traditional mechanical anchor. Its use could in fact shatter the wall, following a greater pressure exerted during the fixing phase.

A technique that allows you to anchor a metal bar in the wall through a glue special inserted into the hole. Once hardened, the screw will be locked. An uncomplicated procedure but which requires competence in the intervention and knowledge in the application of the right products.

Read also: External railings

Let’s find out in our buying guide how chemical anchors work, the types, the capacity and all the other characteristics of this fixing system.

What are chemical anchors?

The chemical anchors represent the solution in transfer loads on masonry, cement and concrete. In addition to the heavier structural workings, there are several common situations in which they can be particularly useful, for example for attach shelves or lamps to the walls of the house, in the assembly of railings, in the construction of canopies.

Whenever the use of mechanical anchors involves the risk of cracks forming on the walls, chemical anchors must be preferred. To this end, recourse is made to special synthetic resins for filling holes, generating the double advantage of improve the tightness of screws and walls.

Generally speaking, chemical anchors are extremely useful in renovations and find frequent application in a multitude of domestic uses.

How are chemical anchors used?

The operation of the chemical anchors is based on the filling of holes with synthetic resins. The purpose is to increase the tightness of the screw inserted inside. These special adhesives harden and guarantee a greater holding of the anchor. In this way the screw and the wall become one, ensuring considerable solidity.

For a correct functioning of the chemical plug it is therefore essential to make use of special resins, the latter characterized by high mechanical strength and speed in hardening.

You may be interested in: Balcony railings

The so-called are commercially available two-component resins, whose application takes place using a gun and a special dispenser. Once opened, the resin is released through a spiral nozzle.

Chemical dowels scope how it works

A fastening technique that stands out for its extreme versatility, even in the presence of one wall with solid or hollow bricks. Usually the steps to take are as follows:

- Drilling

- Cleaning the hole from dust

- Inserting the vial (resin)

- Inserting the bolt or bar

- Rotation and hardening.

Therefore it is essential to inject the resin into the hole before inserting the bar, ensuring a greater airtightness and impermeability to water.

You can insert bars of any length and into the hole increase its range. A larger diameter therefore leads to an increase in load capacity. The chemical anchors therefore allow the flow distribution over the whole area unlike mechanical ones.

Types of resin

At the basis of the functioning of the chemical anchors, the choice of the type of resins and adhesives. A first important classification must be made on the basis of hardening times. A second, taking into account the composition. In this regard, it is necessary to distinguish:

- Polyester

- Epoxy resins

- Vinylester.

The polyester resins they are to be excluded for wet concrete wall works, as they can compromise the solidity and resistance of the entire wall. Therefore, they have a limit in their application due to problems related to alkaline hydrolysis. In this case, the vinylester resins capable of guaranteeing greater mechanical resistance.

In all jobs where more ductility is required, such as holes of a certain width, it is better to prefer epoxy resins, among other things characterized by longer hardening times than the other types described above.

Advantages chemical dowels

From what has been described up to now, the use of chemical anchors has many advantages. One of the main ones is withstand high loads and ensure a remarkable speed of application. Among the strengths of this fixing solution we indicate the resistance to heat and chemical materials, greater durability over time, high anchoring properties. The positives don’t end here though:

- Filling of irregular holes

- Homogeneous pressure distribution

- Dimensions of different fixing diameters

- Edge installation

- Adaptability to multiple materials

Chemical anchor vs mechanical anchor: difference

The chemical anchor ensures one more flexibility compared to a mechanical anchoring. The latter, when inserted into the mural work, is subject to expand during the tightening phase. With brick and stone, for example, using screws that generate expansion in the anchors can affect the integrity of the entire structure and give rise to cracks.

Through the chemical injection into the hole and the use of a threaded rod inside it, the anchoring product is able to withstand considerable load capacities. While It does not “stress” the structure too much but distributes the pressure exerted evenly.

Price chemical dowels

The prices of dowels for chemical anchors are different based on the composition, type and set of accessories included (for example threaded rods). They still present costs within everyone’s reach. Only in some cases they require a few tens of euros more, for specific accessories and high performance anchors for heavy loads. Among the most supplied several specialized chains (Leroy Merlin, Bricoman) and industry brands (for example i Hilti chemical anchors).

Leroy Merlin chemical dowels

Extensive catalog on the online site and in the shops of the well-known brand Leroy Merlin. Dowels, cartridges and chemical anchoring sets are available Fischer line for multiple uses. Prices start at a few euros.

Bricoman chemical dowels

Here is another very popular brand, with a chain of stores scattered throughout the country and a vast online catalog to buy comfortably from PC, smartphone and tablet. Several proposals for chemical anchors of the Fischer, Friulsider, G&B and Wurth lines. Prices for dowels and accessories included from 1 € to a maximum of 86 €.

Chemical anchors: photos and images

Below is a complete gallery of images to describe the fixing technique of the chemical anchors and the main characteristics. It can be useful in your future interior and exterior works.