Autoclave pressure switch. Definition and operation of the water system. Pressure switch adjustment and maintenance operations. Problems that poor maintenance can cause. Electronic autoclave connection, operation.

Her correct and regular maintenance it allows any system to function precisely, recording any variation in the system pressure and reacting accordingly.

Pressure switch: what it is

In general terms, the pressure switch is a two-state device, open or closed, and which is inserted into any machinery that has to manage the pressure of a fluid.

So it is a device that detects the change in pressure and responds with the opposite phases of switching the system on and off.

Read also: House fire extinguishing system

In concrete terms, a part of the mechanism is immersed in the fluid it has to regulate and activates a system of levers that activate or deactivate the switch.

His use it is common in all of those systems that operate under pressure and can indifferently concern the electric current, the flow of natural gas or liquids, or the creation of steam.

The simplest model consists of a toggle switch, making sure that, in case of emergency or when a special alarm sounds, it is sufficient to lower the lever to switch it off.

Autoclave pressure switch: operation

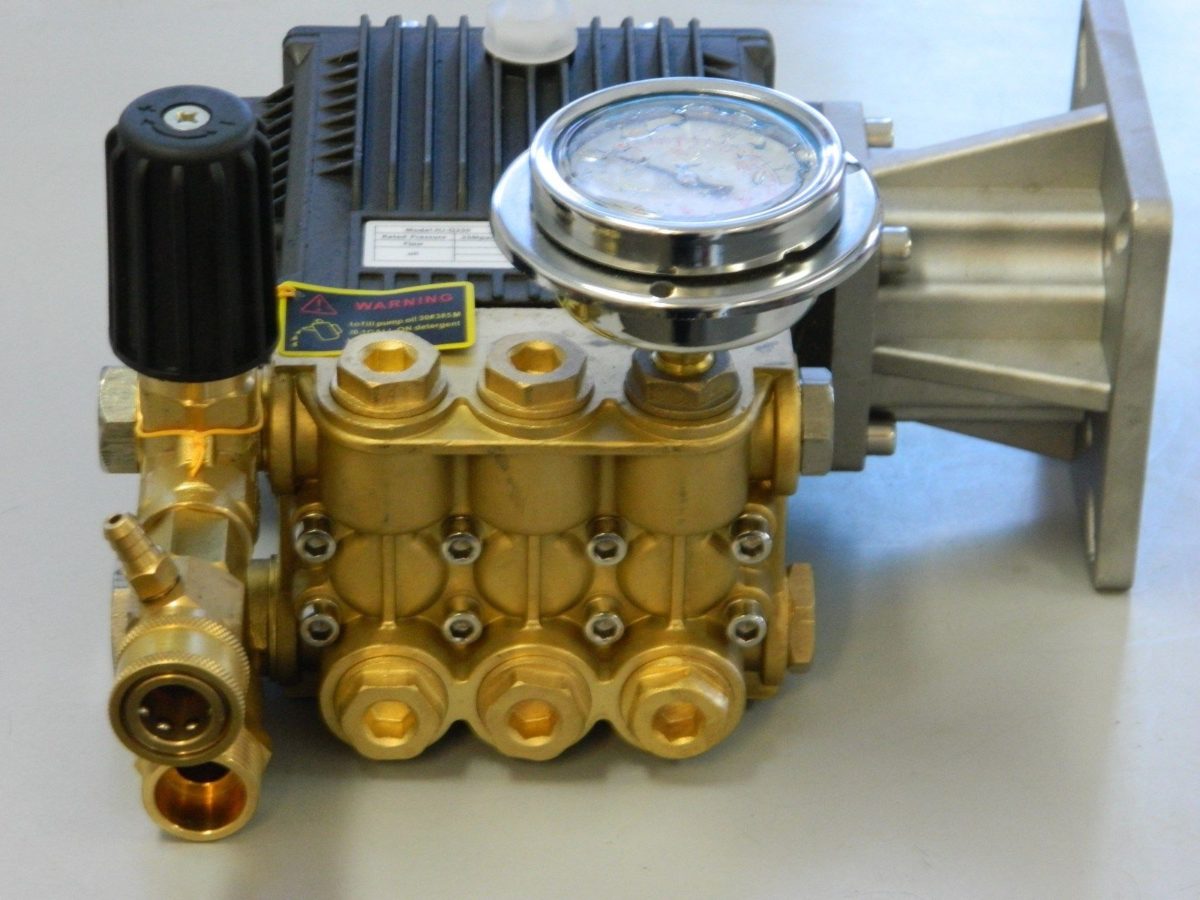

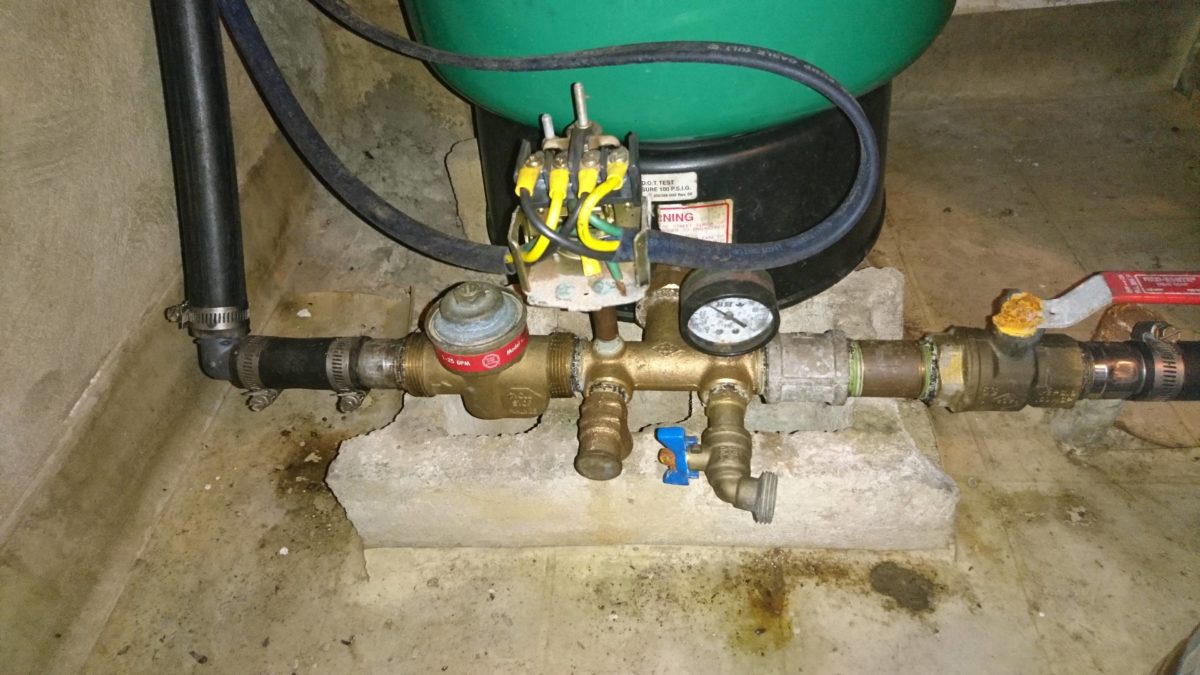

- water tank, regularly connected to the water supply,

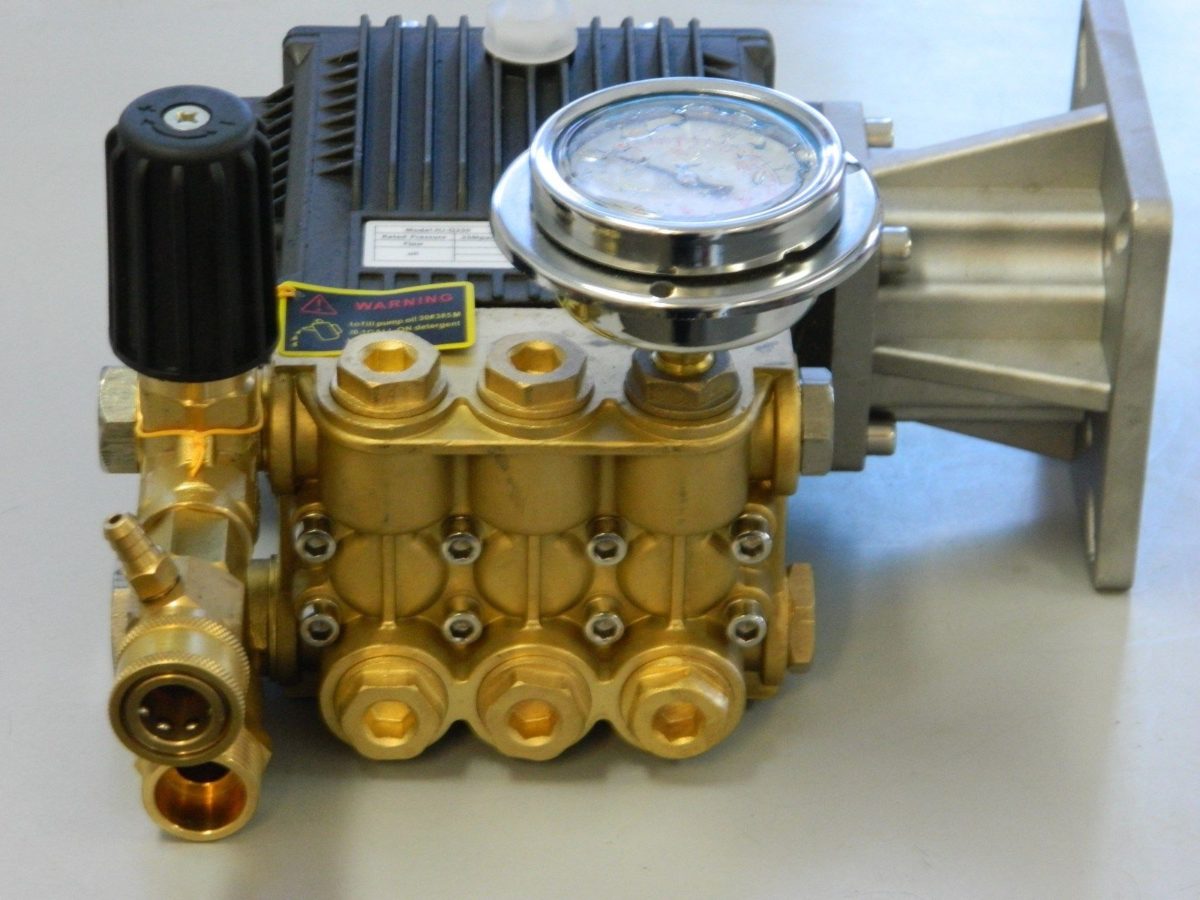

- electric pump,

- expansion vessel with air chamber,

- pressure switch.

The operation of the pressure switch it is very simple to explain.

It is a pressure switch having the function of converting the pressure of a fluid, such as water for example, into a mechanical movement.

This movement determines theactivation or deactivation of the electric pump. In this way, by calibrating the power required for operation, it is ensured that the system stops when the desired value is reached.

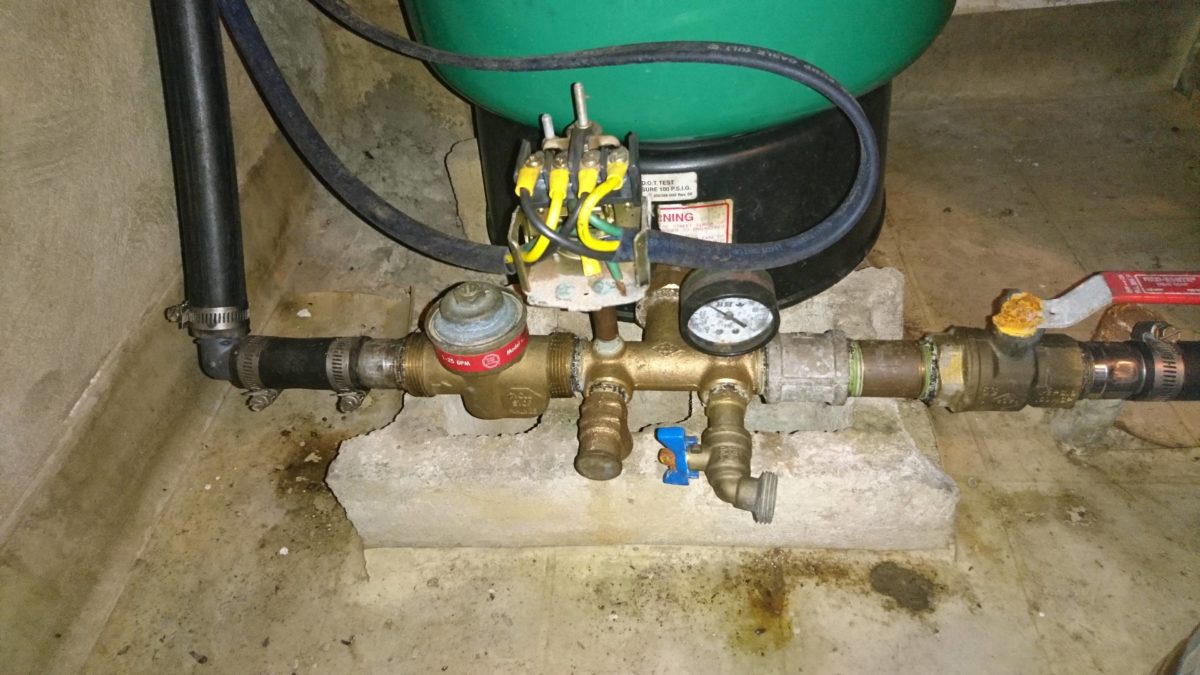

In the case of the home water system, the water from the water supply enters the expansion vessel, compressing the air. The pressure increases and when it reaches the set value, the pressure switch switches off the pump.

You may be interested in: Sensor taps: when hygiene comes first

The moment it comes opened a tap in the house, the pressure drops up to the minimum calibrated value, making the pump switch on again.

In this, the pressure switch determines the correct performance of the home water system by controlling the pressure.

Autoclave pressure switch: adjustment

Do you want design advice on how to furnish? Join the group

Therefore, although there are many models, the initial calibration provides that the autoclave is activated when the pressure reaches a level lower than that entered at the time of manufacture.

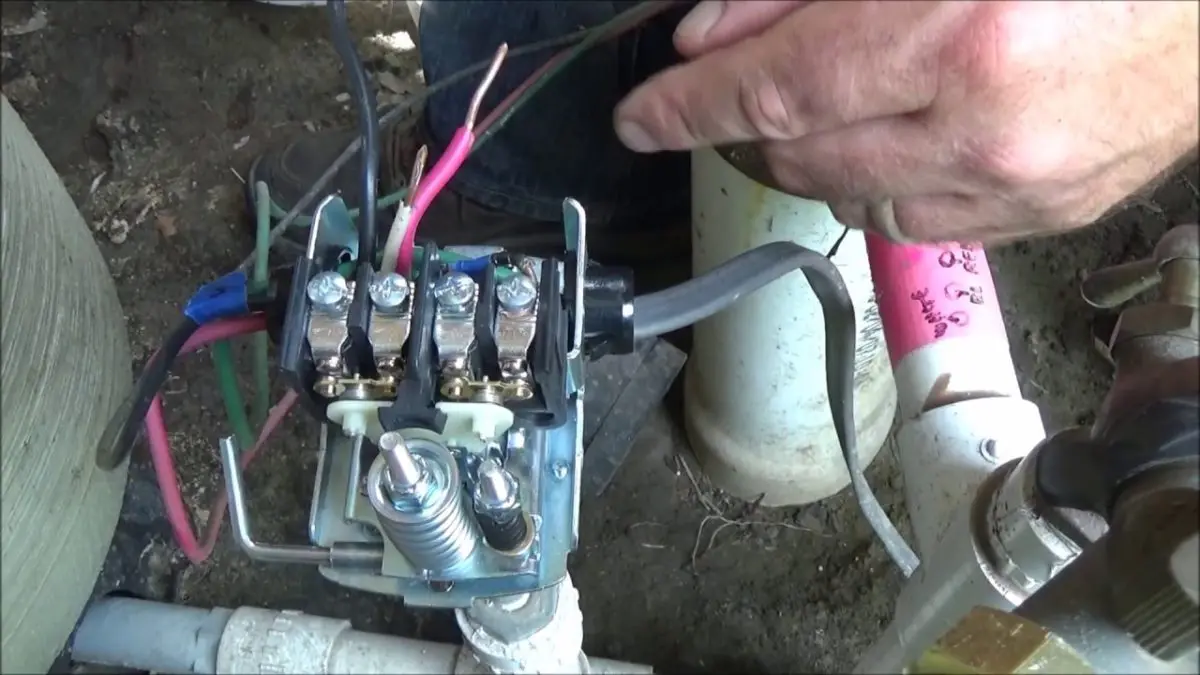

There adjustment phase of the set value is very simple. After reading the system use and maintenance manual, wear a pair of gloves and a screwdriver.

First, write down the pressure values at which the pressure switch must work on a piece of paper; therefore proceed to empty the water from the tank.

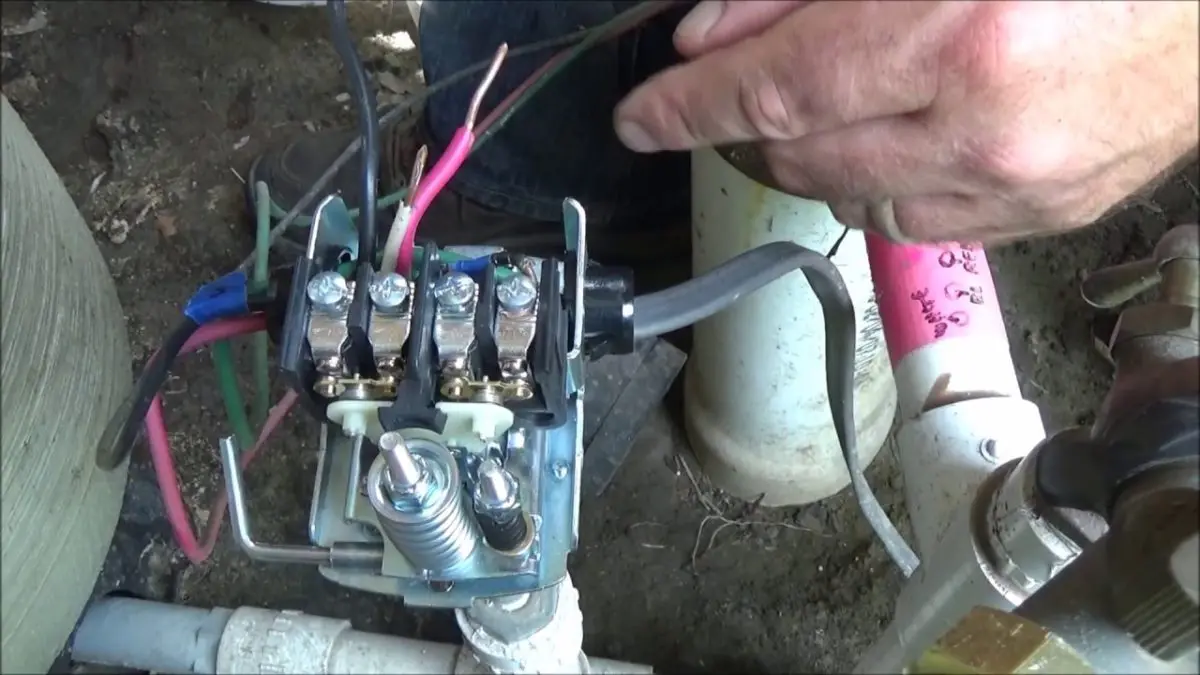

Only afterwards, open the box where the pressure switch is present; here we can see two dice:

- a nut, called differential, determines the pressure difference between the start and stop phases; is determined for the start-up phase and essentially regulates low pressure values,

- the second datum operates on disconnection, ie it determines the pressure value at which the pump must stop.

Equipped with screwdriver, intervene on the differential nut putting it to a minimum, simply loosening it completely. Act then on the other nut, screwing it until the desired value is obtained.

Remember that in this way we will have adjusted the point where the pump will stop.

Return to the differential nut, in order to adjust, according to our needs, the starting point of the pump.

Once we have made the adjustment, refit the lid and put it into operation regularly to make sure everything is in order.

Generally, the operating value of normal aqueducts is between 2 and 4 atmospheres, with slight changes that may be dictated by the difficulty of getting water to the upper floors of an apartment building and therefore the need for greater pressure.

Autoclave pressure switch: maintenance

The maintenance procedures are therefore fundamental and must be repeated during the year several times, intervening, if necessary, with cleaning even more assiduously.

The malfunction of the pressure switch it would block the entire water system, as it is no longer possible to have water in the house or with insufficient pressure for daily operations.

What is needed

Before starting with the actual phase, it is necessary to keep the use and maintenance booklet available for consultation in case of need, as well as a series of elementary tools, namely:

- Allen key,

- slotted and Phillips screwdrivers,

- a thin steel or iron wire,

- a common descaling product.

How to do

First of all it is necessary turn off the power, turning off the system and placing it on OFF.

Open the tap to release the pressure; at this point, the pressure switch can be disassembled by carefully following the instructions given in the instruction booklet.

Taking great care, use the wire to remove debris and limescale that have accumulated, paying attention to the delicate membrane inside the pressure switch.

At this point, a further degree of accuracy is the complete disassemblyby placing the non-electrical components in a bain-marie in a basin with the descaling product.

A couple of hours they should be sufficient for complete removal of dirt; after which, carefully dried, the final assembly work can be carried out.

Returning to commissioning the system, the regular loading and unloading cycles will indicate normal and correct operation.

Autoclave pressure switch: problems

There are several problems that can occur with a malfunction of an pressure switch and which may lead to the call of an expert technician:

- autoclave connects and disconnects continuously

- autoclave does not switch off the pump,

- the pressure switch is leaking water,

- the membrane of the autoclave breaks after a short time.

Autoclave pressure switch. Definition and operation of the water system. Pressure switch adjustment and maintenance operations. Problems that poor maintenance can cause. Electronic autoclave connection, operation.

Her correct and regular maintenance it allows any system to function precisely, recording any variation in the system pressure and reacting accordingly.

Pressure switch: what it is

In general terms, the pressure switch is a two-state device, open or closed, and which is inserted into any machinery that has to manage the pressure of a fluid.

So it is a device that detects the change in pressure and responds with the opposite phases of switching the system on and off.

Read also: House fire extinguishing system

In concrete terms, a part of the mechanism is immersed in the fluid it has to regulate and activates a system of levers that activate or deactivate the switch.

His use it is common in all of those systems that operate under pressure and can indifferently concern the electric current, the flow of natural gas or liquids, or the creation of steam.

The simplest model consists of a toggle switch, making sure that, in case of emergency or when a special alarm sounds, it is sufficient to lower the lever to switch it off.

Autoclave pressure switch: operation

- water tank, regularly connected to the water supply,

- electric pump,

- expansion vessel with air chamber,

- pressure switch.

The operation of the pressure switch it is very simple to explain.

It is a pressure switch having the function of converting the pressure of a fluid, such as water for example, into a mechanical movement.

This movement determines theactivation or deactivation of the electric pump. In this way, by calibrating the power required for operation, it is ensured that the system stops when the desired value is reached.

In the case of the home water system, the water from the water supply enters the expansion vessel, compressing the air. The pressure increases and when it reaches the set value, the pressure switch switches off the pump.

You may be interested in: Sensor taps: when hygiene comes first

The moment it comes opened a tap in the house, the pressure drops up to the minimum calibrated value, making the pump switch on again.

In this, the pressure switch determines the correct performance of the home water system by controlling the pressure.

Autoclave pressure switch: adjustment

Do you want design advice on how to furnish? Join the group

Therefore, although there are many models, the initial calibration provides that the autoclave is activated when the pressure reaches a level lower than that entered at the time of manufacture.

There adjustment phase of the set value is very simple. After reading the system use and maintenance manual, wear a pair of gloves and a screwdriver.

First, write down the pressure values at which the pressure switch must work on a piece of paper; therefore proceed to empty the water from the tank.

Only afterwards, open the box where the pressure switch is present; here we can see two dice:

- a nut, called differential, determines the pressure difference between the start and stop phases; is determined for the start-up phase and essentially regulates low pressure values,

- the second datum operates on disconnection, ie it determines the pressure value at which the pump must stop.

Equipped with screwdriver, intervene on the differential nut putting it to a minimum, simply loosening it completely. Act then on the other nut, screwing it until the desired value is obtained.

Remember that in this way we will have adjusted the point where the pump will stop.

Return to the differential nut, in order to adjust, according to our needs, the starting point of the pump.

Once we have made the adjustment, refit the lid and put it into operation regularly to make sure everything is in order.

Generally, the operating value of normal aqueducts is between 2 and 4 atmospheres, with slight changes that may be dictated by the difficulty of getting water to the upper floors of an apartment building and therefore the need for greater pressure.

Autoclave pressure switch: maintenance

The maintenance procedures are therefore fundamental and must be repeated during the year several times, intervening, if necessary, with cleaning even more assiduously.

The malfunction of the pressure switch it would block the entire water system, as it is no longer possible to have water in the house or with insufficient pressure for daily operations.

What is needed

Before starting with the actual phase, it is necessary to keep the use and maintenance booklet available for consultation in case of need, as well as a series of elementary tools, namely:

- Allen key,

- slotted and Phillips screwdrivers,

- a thin steel or iron wire,

- a common descaling product.

How to do

First of all it is necessary turn off the power, turning off the system and placing it on OFF.

Open the tap to release the pressure; at this point, the pressure switch can be disassembled by carefully following the instructions given in the instruction booklet.

Taking great care, use the wire to remove debris and limescale that have accumulated, paying attention to the delicate membrane inside the pressure switch.

At this point, a further degree of accuracy is the complete disassemblyby placing the non-electrical components in a bain-marie in a basin with the descaling product.

A couple of hours they should be sufficient for complete removal of dirt; after which, carefully dried, the final assembly work can be carried out.

Returning to commissioning the system, the regular loading and unloading cycles will indicate normal and correct operation.

Autoclave pressure switch: problems

There are several problems that can occur with a malfunction of an pressure switch and which may lead to the call of an expert technician:

- autoclave connects and disconnects continuously

- autoclave does not switch off the pump,

- the pressure switch is leaking water,

- the membrane of the autoclave breaks after a short time.