Prefabricated garages are a cheaper alternative to building brick garages. They can be made in different materials from wood, to concrete, to galvanized sheets. Choosing prefabricated garages allows you to reduce construction times and lower costs compared to traditional garages. Discover all the advantages of a prefabricated garage.

Is your house small and there is never enough space available? Have you ever thought about building a prefab garage? If you have space in the garden, why not resort to the construction of a prefabricated garage? This way you will have additional space to park the car, to store boxes or simply to arrange equipment or materials that you rarely use. What does it take to build a prefab garage? Which materials You can choose? Wood, iron, zinc and concrete. Discover the materials that best suit your needs. Permits and costs.

Read also: Prefabricated roof

How a prefab garage is made

As the word the prefab garage is one structure which is built by the manufacturer and then assembled on site where it needs to be built. Could be made of different materials from wood, to iron to concrete. Depending on the type of material used, the prefabricated garage can require maintenance over time and be available at different costs.

The prefabricated garage consists of modules which are then assembled on the place where the garage will be built. Furthermore, depending on the type of manufacturing material, assembly may require the presence of expert personnel and specialized and of mechanical means for lifting such as a crane.

Why choose a prefab garage

If you need extra space in your yard, the prefab garage is a great one solution to obtain additional space without spending too much. Compared to normal brick built garages built on site, a prefabricated garage has reduced costs. But if you want to know in detail all the advantages we list them below.

- Speed of construction. Compared to a brick garage, a prefabricated one provides construction time a lot short.

- Possibility of travel. Prefabricated garages consist of modules that are assembled. It is evident that compared to those in masonry can be moved and transported with ease.

- Less bureaucracy. Building a prefab garage requires faster paperwork compared to building a traditional garage.

- Savings. As already mentioned the prefabricated garages depending on the material used have costs very lower compared to those in masonry.

You might be interested in: Stacking a prefabricated building: legislation, how to do it, costs

Prefabricated garages: construction materials

They exist on the market different types of garages, in addition to the dimensions, the various models also differ in the materials used in construction and for the intended use.

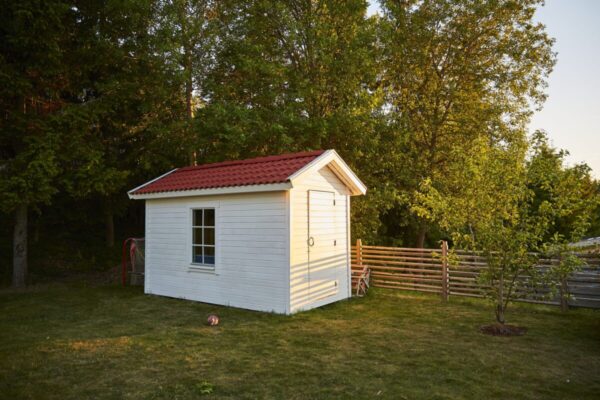

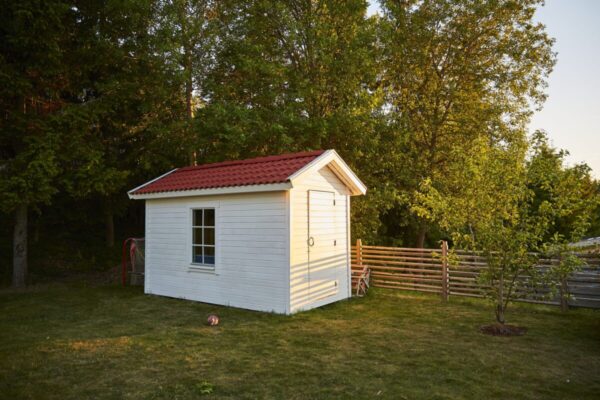

- Wood. It’s the kind of more ecological prefab garage. Unlike the other materials though requires more frequent maintenance to preserve its durability over time. It’s the garage type more suitable for the garden, natural wood will blend perfectly with the surrounding environment.

- Galvanized sheet. Among the various types, the garage in galvanized sheet metal and the cheaper solution, but also resistant. Easy to assemble, it does not require the presence of specialized personnel, you just need a little DIY knowledge to assemble or disassemble the structure. For the same reasons it is also the easiest solution to move.

- Insulated prefabricated garage. It is a well insulated structure made with polyurethane foam and galvanized sheets. These are sandwich panels which are in able to insulate the garage well with respect to the external environment.

- Concrete. And the most resistant type and also the heaviest. Made in reinforced concrete, it’s composed by modules that are then assembled on site. Has higher costs compared to other types. The precast concrete garages they adapt perfectly to any type of environment and they have one long lasting. Being very heavy, the concrete modules to be moved and assembled need a crane for lifting.

Do you want design advice on how to furnish? Join the group

How to assemble prefabricated garages

How does the assembly of prefabricated garages? Whatever type of prefab garage you have chosen to build, the first step is create a concrete base on the ground on which they will then go assembled the various modules of the garage.

What are the permissions?

Before starting the construction of a prefabricated garage, whatever type it belongs to it is however advisable to inquire about permissions which are needed at the municipal technical offices.

Though the legislation varies according to the municipal regulations, in general if you intend to build a concrete garage it will take a permission to build, Why the construction assumes a fixed character and lasting.

In the case instead of prefabricated garages not anchored to the ground, being structures from temporary character it will be enough a simple wake, a communication of the start of business.

What are the costs to be faced?

How much does it cost to build a prefab garage? As anticipated costs of a prefabricated garage are inferior compared to a brick garage. Among the prefabricated garages the costs vary not only according to the size of the structure, but also according to the type of used material for the construction. There the most expensive type is the prefabricated concrete garage. In addition, the costs also affect the costs need to contact expert personnel for the construction and rental of mechanical means for lifting modules, such as cranes.

Prefabricated garages: images and photos

Prefabricated garages allow you to have additional space for your home. They can be made of wood, galvanized sheet, insulated or concrete. Building a prefabricated garage has numerous advantages from cost savings to construction times, to the necessary permits. Browse the gallery and find the solution that suits you best.

Prefabricated garages are a cheaper alternative to building brick garages. They can be made in different materials from wood, to concrete, to galvanized sheets. Choosing prefabricated garages allows you to reduce construction times and lower costs compared to traditional garages. Discover all the advantages of a prefabricated garage.

Is your house small and there is never enough space available? Have you ever thought about building a prefab garage? If you have space in the garden, why not resort to the construction of a prefabricated garage? This way you will have additional space to park the car, to store boxes or simply to arrange equipment or materials that you rarely use. What does it take to build a prefab garage? Which materials You can choose? Wood, iron, zinc and concrete. Discover the materials that best suit your needs. Permits and costs.

Read also: Prefabricated roof

How a prefab garage is made

As the word the prefab garage is one structure which is built by the manufacturer and then assembled on site where it needs to be built. Could be made of different materials from wood, to iron to concrete. Depending on the type of material used, the prefabricated garage can require maintenance over time and be available at different costs.

The prefabricated garage consists of modules which are then assembled on the place where the garage will be built. Furthermore, depending on the type of manufacturing material, assembly may require the presence of expert personnel and specialized and of mechanical means for lifting such as a crane.

Why choose a prefab garage

If you need extra space in your yard, the prefab garage is a great one solution to obtain additional space without spending too much. Compared to normal brick built garages built on site, a prefabricated garage has reduced costs. But if you want to know in detail all the advantages we list them below.

- Speed of construction. Compared to a brick garage, a prefabricated one provides construction time a lot short.

- Possibility of travel. Prefabricated garages consist of modules that are assembled. It is evident that compared to those in masonry can be moved and transported with ease.

- Less bureaucracy. Building a prefab garage requires faster paperwork compared to building a traditional garage.

- Savings. As already mentioned the prefabricated garages depending on the material used have costs very lower compared to those in masonry.

You might be interested in: Stacking a prefabricated building: legislation, how to do it, costs

Prefabricated garages: construction materials

They exist on the market different types of garages, in addition to the dimensions, the various models also differ in the materials used in construction and for the intended use.

- Wood. It’s the kind of more ecological prefab garage. Unlike the other materials though requires more frequent maintenance to preserve its durability over time. It’s the garage type more suitable for the garden, natural wood will blend perfectly with the surrounding environment.

- Galvanized sheet. Among the various types, the garage in galvanized sheet metal and the cheaper solution, but also resistant. Easy to assemble, it does not require the presence of specialized personnel, you just need a little DIY knowledge to assemble or disassemble the structure. For the same reasons it is also the easiest solution to move.

- Insulated prefabricated garage. It is a well insulated structure made with polyurethane foam and galvanized sheets. These are sandwich panels which are in able to insulate the garage well with respect to the external environment.

- Concrete. And the most resistant type and also the heaviest. Made in reinforced concrete, it’s composed by modules that are then assembled on site. Has higher costs compared to other types. The precast concrete garages they adapt perfectly to any type of environment and they have one long lasting. Being very heavy, the concrete modules to be moved and assembled need a crane for lifting.

Do you want design advice on how to furnish? Join the group

How to assemble prefabricated garages

How does the assembly of prefabricated garages? Whatever type of prefab garage you have chosen to build, the first step is create a concrete base on the ground on which they will then go assembled the various modules of the garage.

What are the permissions?

Before starting the construction of a prefabricated garage, whatever type it belongs to it is however advisable to inquire about permissions which are needed at the municipal technical offices.

Though the legislation varies according to the municipal regulations, in general if you intend to build a concrete garage it will take a permission to build, Why the construction assumes a fixed character and lasting.

In the case instead of prefabricated garages not anchored to the ground, being structures from temporary character it will be enough a simple wake, a communication of the start of business.

What are the costs to be faced?

How much does it cost to build a prefab garage? As anticipated costs of a prefabricated garage are inferior compared to a brick garage. Among the prefabricated garages the costs vary not only according to the size of the structure, but also according to the type of used material for the construction. There the most expensive type is the prefabricated concrete garage. In addition, the costs also affect the costs need to contact expert personnel for the construction and rental of mechanical means for lifting modules, such as cranes.

Prefabricated garages: images and photos

Prefabricated garages allow you to have additional space for your home. They can be made of wood, galvanized sheet, insulated or concrete. Building a prefabricated garage has numerous advantages from cost savings to construction times, to the necessary permits. Browse the gallery and find the solution that suits you best.